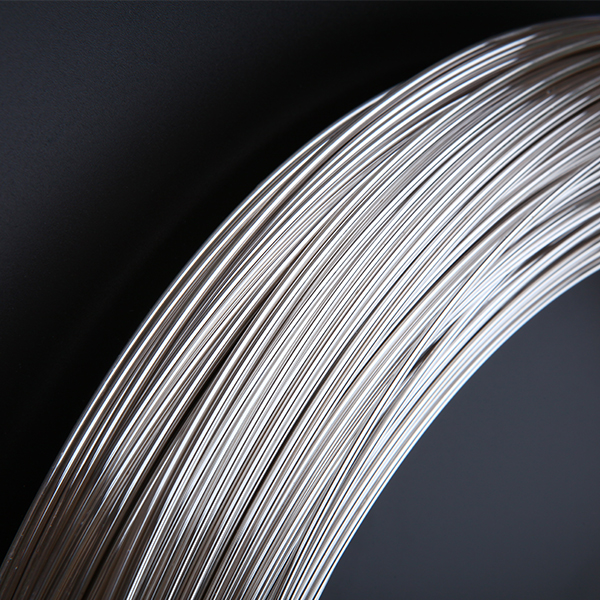

Silver Alloy Wires

| Application: |

| Contactors, circuit breakers, thermostats, intelligent switches, etc |

| The Material: |

| Ag/FAg,AgNi,AgCdO,AgZnO,AgSnO2,AgSnO2In2O3 |

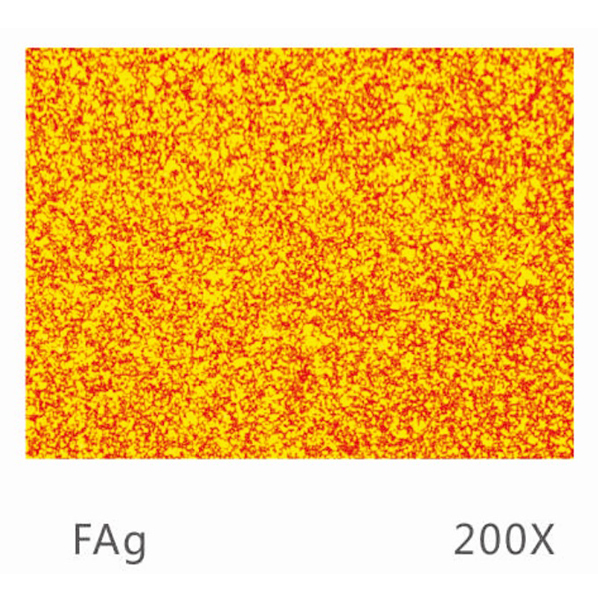

Ag- FAg

1. Microstructure

2. General Description

Silver and fine grain silver (FAg) possess very high electrical and thermal conductivity, low and stable contact resistance, and good workability. For silver resistance to arc erosion and contact welding are limited, mechanical strength is low, Due to the small quantity of nickel in the fine grain silver, resistance to arc erosion and mechanical strength are higher than that of silver.

3. Application Scope

Widely used in low current devices, such as relays, timers, auxiliary switches for household appliances , control switches, etc.

4. Material Properties

|

Ag |

FAg |

|||

|

Tips |

Wires |

Tips |

Wires |

|

| Ag Content (wt.%) |

≥99.95 |

≥99.95 |

99.85 |

99.85 |

| Density (g/cm3) |

≥10.48 |

≥10.48 |

≥10.40 |

≥10.40 |

| Elec. Resistivity (pQ•cnn) |

≤2.10 |

≥1.80 |

≥2.10 |

≥1.85 |

| Hardness HV |

≥40 |

≥60 |

≥45 |

≥65 |

| Tensile Strength (MPa) |

|

230-380 |

|

250-380 |

| Elongation (%) |

|

2-30 |

|

2-30 |

| Manufacturing process | Extruding-Rolling | Extruding -Drawing | Extruding-Rolling | Extruding -Drawing |

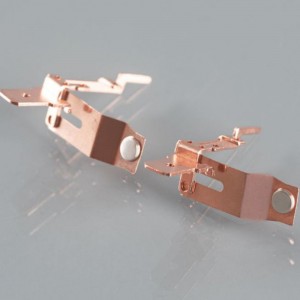

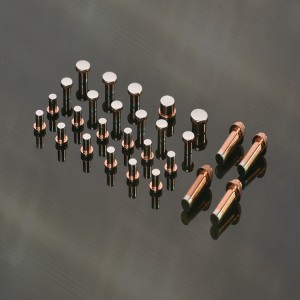

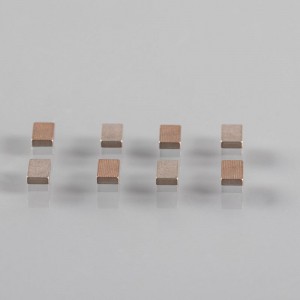

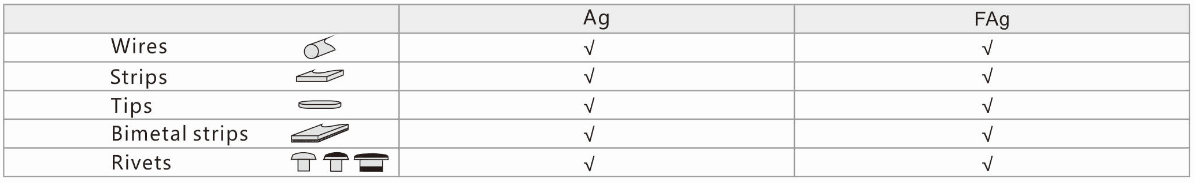

5. Product Types

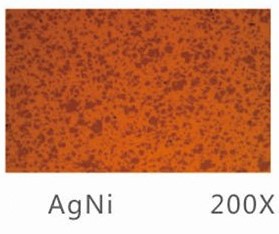

AgNi

1. Microstructure

2. General Description

AgNi materials have higher resistance to arc erosion and contact welding than Ag or FAg. Both properties are improved with increasing Ni content. All AgNi materials show good workability and are easy to weld to contact supports. Low tendency towards material transfer in DC applications. AgNi materials are environment-protective materials.

3. Application Scope

AgNi contact materials find a wide range of application in low voltage switching devices. They are used in relays, small contactors, light switches, temperature controllers as well as in protective switches (they are used in asymmetric contact pairs, for instance, againstAgC, AgZnO orAgSnO2 materials).

4. Material Properties

| Wires |

AgNi |

AgNi |

AgNi |

Ag Ni |

AgN i |

AgNi |

| Ni Content (wt.%) |

10±1 |

12±1 |

15±1 |

15±1 |

20±1 |

30±1 |

| Density (g/cm3) |

≥10.25 |

≥10.20 |

≥10.15 |

≥10.15 |

≥10.05 |

≥9.80 |

| Elec.Resistivity (pC2•cm) |

≤1.95 |

≤2.05 |

≤2.05 |

≤2.10 |

≤2.15 |

≤2.50 |

| Hardness HV |

≥75 |

≥70 |

≥80 |

≥80 |

≥80 |

≥80 |

| Tensile Strength (MPa) |

240-450 |

240-450 |

250-360 |

280-460 |

260-380 |

260-380 |

| Elongation(%) |

5-30 |

5-30 |

5-30 |

5-28 |

2-28 |

2-25 |

| Manufacturing process |

Sintering-Extruding |

|||||

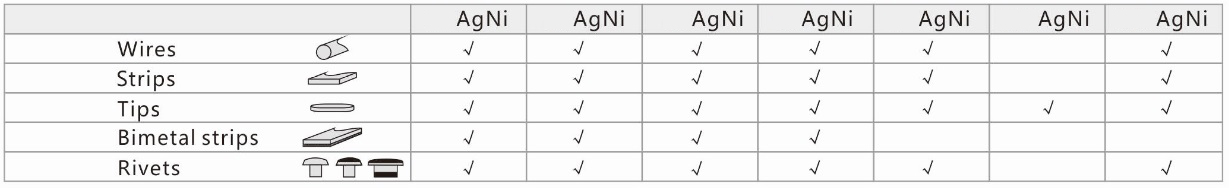

5. Product Types

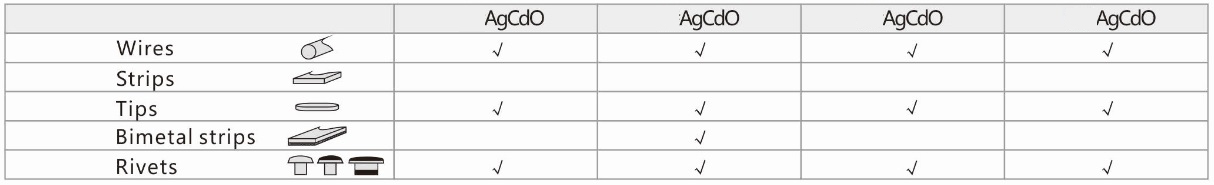

AgCdO

1. Microstructure

2. General Description

AgCdO contacts belong to the group of the most widely used ones on the field of low voltage electric apparatus. They combine a satisfactory resistance against contact welding with a good arc erosion resistance and a fairly low contact resistance over its complete service life. They are produced with two different techniques, pre-oxidation-sintering-extruding and internal oxidation. In both cases Cd0 content may range from 10 to 20wt.%.However,Cd and Cd0 are considered to be hazardous to health and the environment. For this reason the use ofAgCdO materials will be banned in a number of countries.

3. Application Scope

Mainly used in almost every type of low voltage switching devices. They are typically used in microswitches, relays, light switches, contactors, switches for household appliances, some types of protective switches, as well as in certain types of circuit breakers.

4. Material Properties

| Wires | AgCdO | AgCdO | AgCdO | AgCdO | AgCdO | AqCd0 | AgCdO |

| CdO Content(wt.%) | 10±1 | 13.5±1 | 15±1 | 10±1 | 12±1 | 15±1 | 17±1 |

| Density (g/cm3) | ≥10.05 | ≥9.95 | ≥9.90 | ≥10.10 | ≥10.05 | ≥9.95 | ≥9.80 |

| Elec.Resistivity (1.10•cm) | ≤2.25 | ≤2.35 | ≤2.40 | ≤2.10 | ≤2.15 | ≤2.25 | ≤2.40 |

| Hardness HV | ≥70 | ≥75 | ≥75 | ≥70 | ≥70 | ≥75 | ≥75 |

| Tensile Strength (MPa) | 260-350 | 260-380 | 260-380 | 260-350 | 260-380 | 260-380 | 260-400 |

| Elongation(%) | 6-20 | 6-20 | 6-20 | 8-25 | 8-25 | 8-25 | 5-25 |

| Manufacturing process | Pre-oxidation-Sintering-Extruding | Internal Oxidation | |||||

5. Product Types

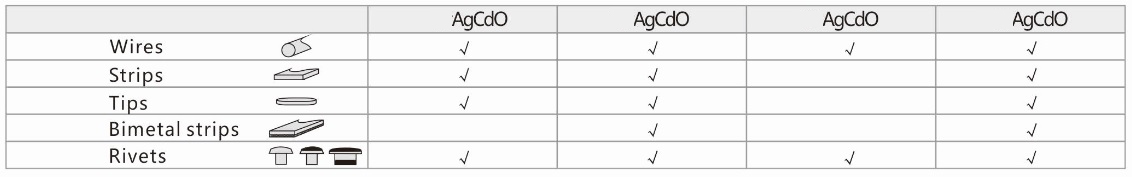

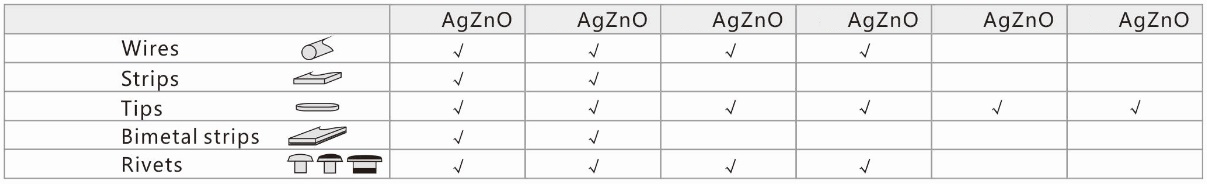

AgZnO

1. Microstructure

2. General Description

A high resistance against contact welding characterizes AgZnO materials. They also show a good resistance against arc erosion. Contact resistance of AgZnO tends to be higher than that of AgCd0. AgZnO can be produced by means of pre-oxidation-sintering —extruding, mixing-compacting-sintering techniques as well as by internal oxidation. AgZnO materials are environment -protective materials.

3. Application Scope

Mainly used in circuit breakers, especially in universal circuit breakers. Other fields of application are motor protective switches, residual current circuit breakers and AC relays.

4. Material Properties

|

Wires |

AgZnO |

AgZnO |

| ZnO Content(wt.%) |

8±1 |

10±1 |

| Density (g/cm3) |

.9.65 |

9.60 |

| Elec.Resistivity (NO•cm) |

2.25 |

2.35 |

| Hardness HV |

E30 |

85 |

| Tensile Strength (MPa) | 285-350 |

285-350 |

| Elongation(%) |

15-25 |

12-20 |

| Manufacturing process |

Pre-oxidation -Sintering-Extruding |

|

5. Product Types

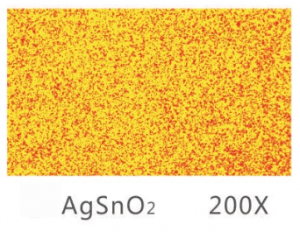

AgSnO2

1. Microstructure

2. General Description

AgSnO2/AgSn021n203 are eco-friendly electrical contact materials. They have good performances in anti-erosion and anti-welding properties, and have good anti-material transfer property in DC switching circuit. The main manufacturing processes are internal oxidation process, pre-oxidation process, powder metallurgy process, chemical coating process, etc.

3. Application Scope

Widely used in various kinds of contactors , relays, circuit breakers and switches, etc.

4. Material Properties

AgSnO2

|

Wires |

AgSnO2 |

AgSnO2 |

AgSnO2 |

AgSnO2 |

AgSn02 |

| SnO2 Content (wt.%) |

10±1 |

10±1 |

12±1 |

12±1 |

15±1 |

| Density (g/cm3) |

≥9.90 |

≥9.95 |

≥9.85 |

≥9.85 |

≥9.5 |

| Elec. Resistivity (pO•cm) |

≤2.15 |

≤2.30 |

≤2.30 |

≤2.30 |

≤2.81 |

| Hardness HV |

≥85 |

≥95 |

≥70 |

≥75 |

≥85 |

| Tensile Strength (MPa) |

295-350 |

290-385 |

230-350 |

230-285 |

250-330 |

| Elongation(%) |

15-25 |

15-25 |

15-25 |

18-30 |

15-25 |

| Manufacturing process |

Pre-oxidation-Sintering-Extruding |

Chemical Coating |

Mixing-Sintering-Extruding |

||

AgSnO2In203

|

Wires |

AgSnO2 |

AgSnO2 |

AgSnO2 |

AgSnO2 |

AgSnO2 |

| Ag Content (wt.%) |

90±1 |

88±1 |

92±1 |

88±1 |

85.5±1 |

| Density (g/cm3) |

≥9.95 |

≥9.95 |

≥9.96 |

≥9.91 |

≥9.72 |

| Elec. Resistivity (10•cm) |

≤2.38 |

≤2.45 |

≤2.25 |

≤2.35 |

≤2.55 |

| Hardness HV |

≥100 |

≥100 |

≥90 |

≥95 |

≥95 |

| Tensile Strength (MPa) |

320-450 |

320-450 |

320-450 |

320-450 |

320-450 |

| Elongation(%) |

15-25 |

15-25 |

18-30 |

18-30 |

18-30 |

| Manufacturing process |

Pre-oxidation-Sintering-Extruding |

Internal Oxidation |

|||

5. Product Types

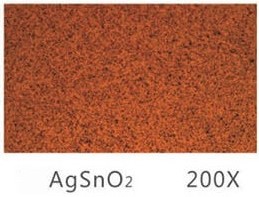

AgSnO2In2O3

1. General Description

2. Microstructure

AgSnO2lAgSn021n203 are eco-friendly electrical contact materials. They have good performances in anti-erosion and anti-welding properties, and have good anti-material transfer property in DC switching circuit. The main manufacturing processes are internal oxidation process, pre-oxidation process, powder metallurgy process, chemical coating process, etc.

3. Application Scope

Widely used in various kinds of contactors , relays, circuit breakers and switches, etc.

4. Material Properties

AgSnO2

|

Wires |

AgSnO2 |

AgSnO2 |

AgSnO2 |

AgSnO2 |

AgSn02 |

| SnO2 Content (wt.%) |

10 ±1 |

10 ±1 |

12±1 |

12±1 |

15 ±1 |

| Density (g/cm3) |

≥9.90 |

≥9.95 |

≥9.85 |

≥9.85 |

≥9.5 |

| Elec. Resistivity (p0•cm) |

≤2.15 |

≤2.30 |

≤2.30 |

≤2.30 |

≤2.81 |

| Hardness HV |

≥85 |

≥95 |

≥70 |

≥75 |

≥85 |

| Tensile Strength (MPa) |

295-350 |

290-385 |

230-350 |

230-285 |

250-330 |

| Elongation(%) |

15-25 |

15-25 |

15-25 |

18-30 |

15-25 |

| Manufacturing process |

Pre-oxidation-Sintering-Extruding |

Chemical Coating |

Mixing-Sintering-Extruding |

||

AgSnO2In203

|

Wires |

AgSnO2 |

AgSnO2 |

AgSnO2 |

AgSnO2 |

AgSnO2 |

| Ag Content (wt.%) |

90±1 |

88±1 |

92±1 |

88±1 |

85.5±1 |

| Density (g/cm3) |

≥9.95 |

≥9.95 |

≥9.96 |

≥9.91 |

≥9.72 |

| Elec. Resistivity (p0•cm) |

≤2.38 |

≤2.45 |

≤2.25 |

≤2.35 |

≤2.55 |

| Hardness HV |

≥100 |

≥100 |

≥90 |

≥95 |

≥95 |

| Tensile Strength (MPa) |

320-450 |

320-450 |

320-450 |

320-450 |

320-450 |

| Elongation(%) |

15-25 |

15-25 |

18-30 |

18-30 |

18-30 |

| Manufacturing process |

Pre-oxidation-Sintering-Extruding |

Internal Oxidation |

|||