High-precision and flexible metal stamping factory

Stamping workshop

SHZHJ has an independent mold R&D department and a professional team of experienced engineers. SHZHJ is well established as one of the premier precision metal stamping suppliers.

Mold Studio

Our experienced staff will work with you on all aspects of metal stamping. From design, prototyping, FAI, PPAP, low-volume production to mid- and high-volume stamping, we will manufacture components to your exact requirements.

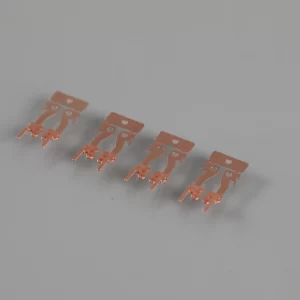

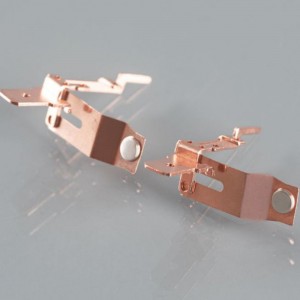

Product

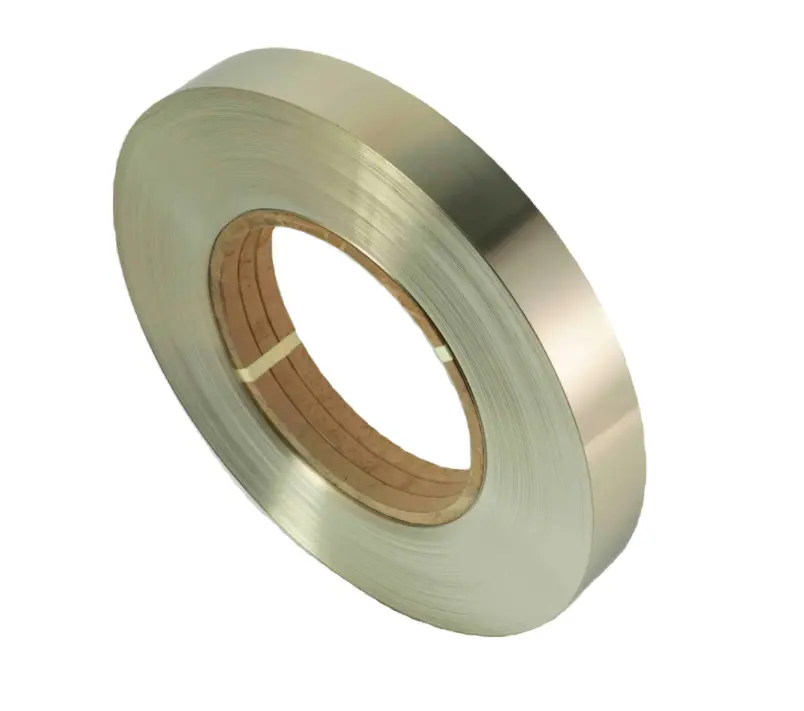

Raw Materials

SHZHJ uses different materials to produce a variety of high-quality products according to the requirements of different industries.Simple strip and clad strip stamping are available.Material thickness range is 5μm to 5mm.

- Copper

- Brass copper

- Beryllium copper

- White copper

- Aluminum

- Steel

- Pure nickel

- Pre-nickel or pre-tin plated materials

- Special customer requirements

PRECISION METAL STAMPING CAPABILITIES

Progressive Die Stamping with:

In Die Tapping and Threaded Inserts

In Die Assembly

In Die Roll Forming with Dovetail Interlocked

Progressive Deep Drawing

Transfer Deep Drawing

Transfer Stamping / Forming on Extruded & Pre-Machined Tube

Reel to Reel Stamping

SHZHJ's stamping process uses top-of-the-line precision metal stamping machines (robotic, manual or progressive lines), our presses range from 45 to 400 tons, CNC equipment is used in conjunction with special universal units, jigs and fixtures to create custom metal Stamping. Parts of any shape can be punched, punched, formed, stenciled, drawn and extruded.

These services are supported by extensive secondary processing capabilities, including mechanical assembly, riveting, tapping and welding, deburring, degreasing and a variety of packaging options.

Why choose SHZHJ -- stamping production

♦ According to the drawing requirements, test the composition and mechanical properties of metal materials to ensure that the materials meet the requirements.

♦ Based on the inquiry, we evaluate 2D and 3D files containing important information including materials, tolerances, critical dimensions and finishing. Depending on the components, the mold department performs different layout designs for product production.

♦ The metal stamping process starts with a flat metal sheet or metal tube. It is inserted into a suitable stamping machine, which shapes the metal by punching, blanking, or stamping. Metal stamping can include automotive stamping, medical stamping, or other stamping, and may require multiple stampings depending on the component.

♦ Most stamped parts require surface treatment. Most stamped parts require plating or different post-processing requirements to protect the part from the environment and ensure a longer product life.

♦ During the production process, the QC department will conduct initial inspection/inspection inspection/final inspection of the products to ensure the provision of quality-assured products.