OEM manufacturer Electrical Tri Metal Rivet – Solid Contact rivet – ZHJ

China OEM manufacturer Electrical Tri Metal Rivet - Solid Contact rivet - ZHJ Manufacturer and Supplier | ZHJ Detail:

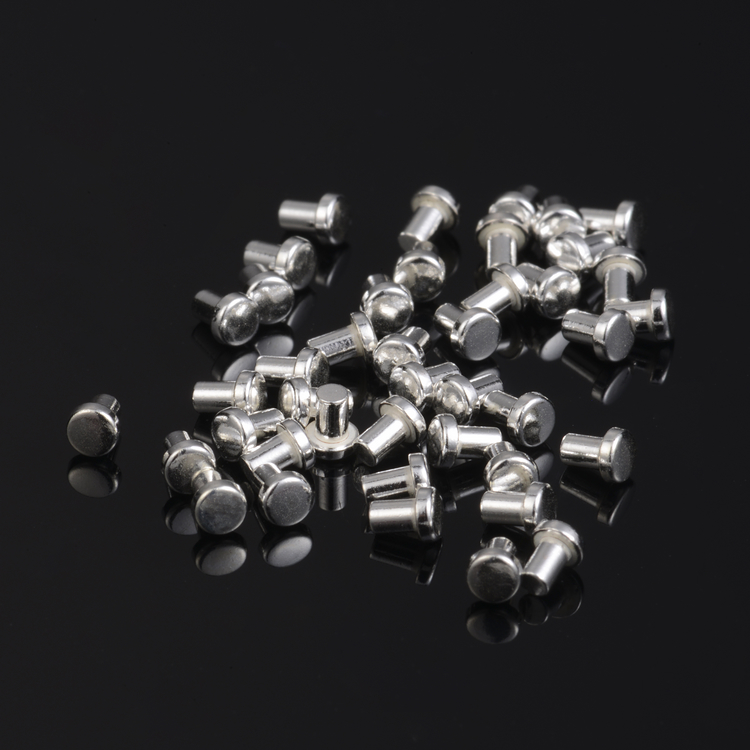

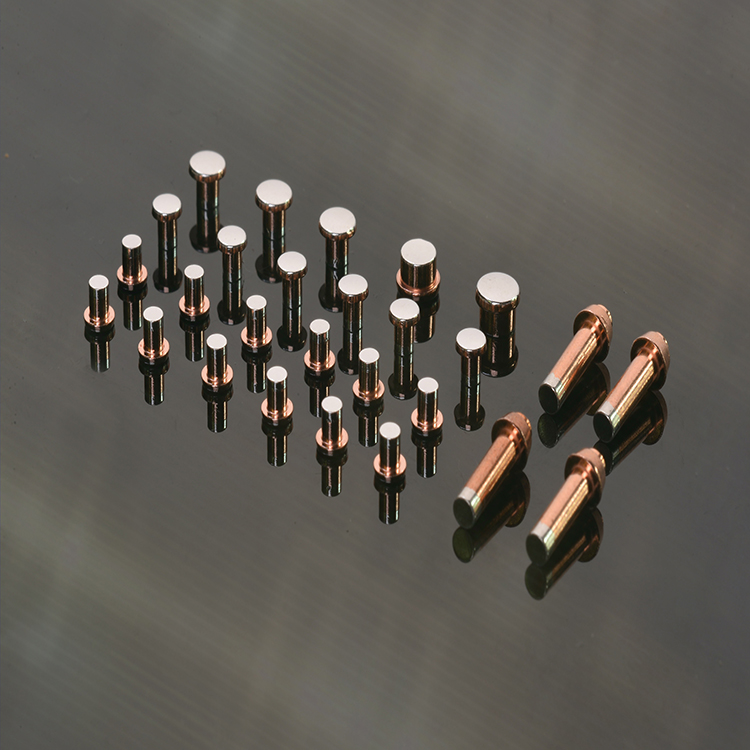

Solid rivets present a larger challenge when de-riveting. The manufactured head must be ground or milled off prior to pushing the rivet back through the hole. When removing solid rivets, the material of the component surrounding the hole must be considered. If the material is softer than the rivet, there is a chance it will be damaged. If the hardness is equal to or harder than the rivet the risk of damage is lower, as it will maintain its shape while the softer rivet is pushed back through. How the rivet was initially formed also plays a role in the de-riveting process. The larger the shank swell created in the forming process, the higher the risk of damage to the surrounding component.

Process flow

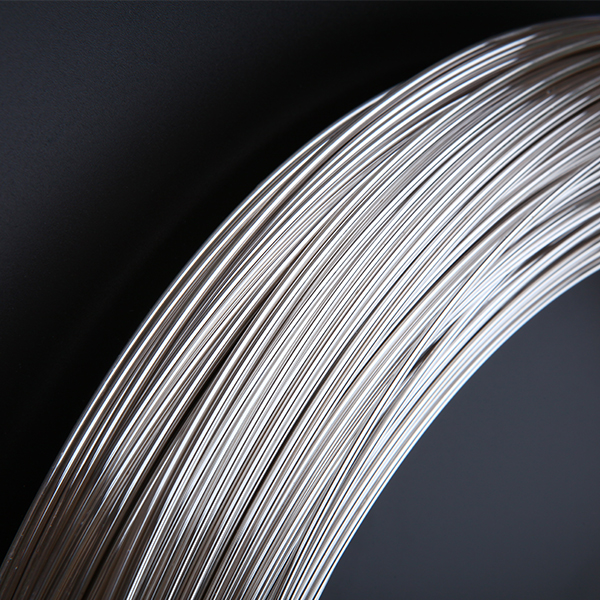

Rivet Making

Annealing

Finishing

Inspection

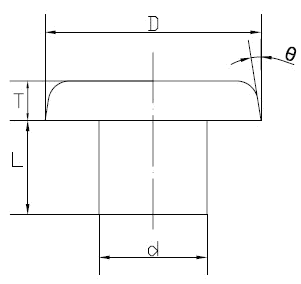

Drawing

Packing

Measure

|

Item |

Head diameter D(mm) |

Head thickness T(mm) |

Foot diameter d(mm) |

Foot length L(mm) |

Sphere radius R(mm) |

| Basic dimension |

1.2~12 |

0.15~3.00 |

0.75~6.00 |

0.45~8.56 |

1.2~40 |

| tolerance |

±0.05 |

-0.02∽ |

-0.02∽ |

±0.05 |

±2 |

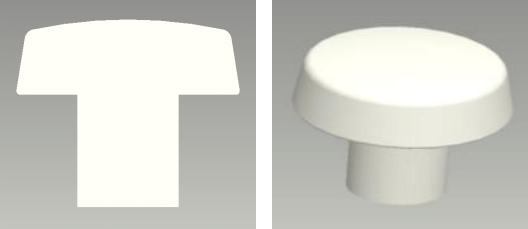

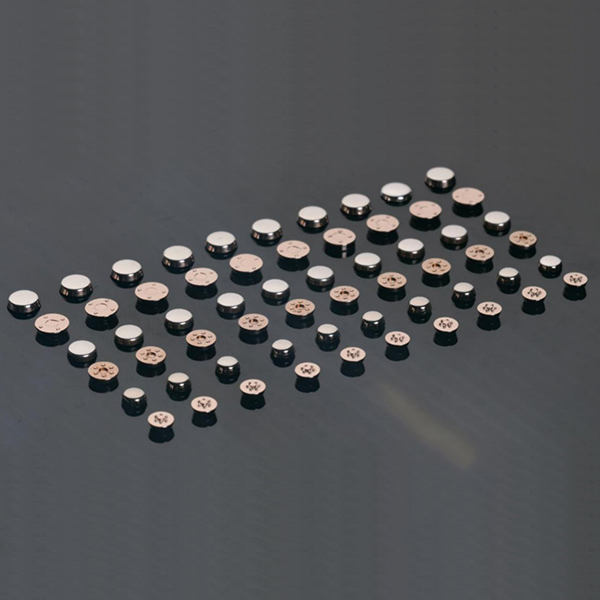

Product detail pictures:

Related Product Guide:

Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction for China OEM manufacturer Electrical Tri Metal Rivet - Solid Contact rivet - ZHJ Manufacturer and Supplier | ZHJ , The product will supply to all over the world, such as: Tunisia , Salt Lake City , Sri Lanka , We critically promise that we deliver all the customers with the best quality solutions, the most competitive prices and the most prompt delivery. We hope to win a resplendent future for customers and ourselves.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.