Hot New Products Electrical Contact Points – Welding Assembly – ZHJ

China Hot New Products Electrical Contact Points - Welding Assembly - ZHJ Manufacturer and Supplier | ZHJ Detail:

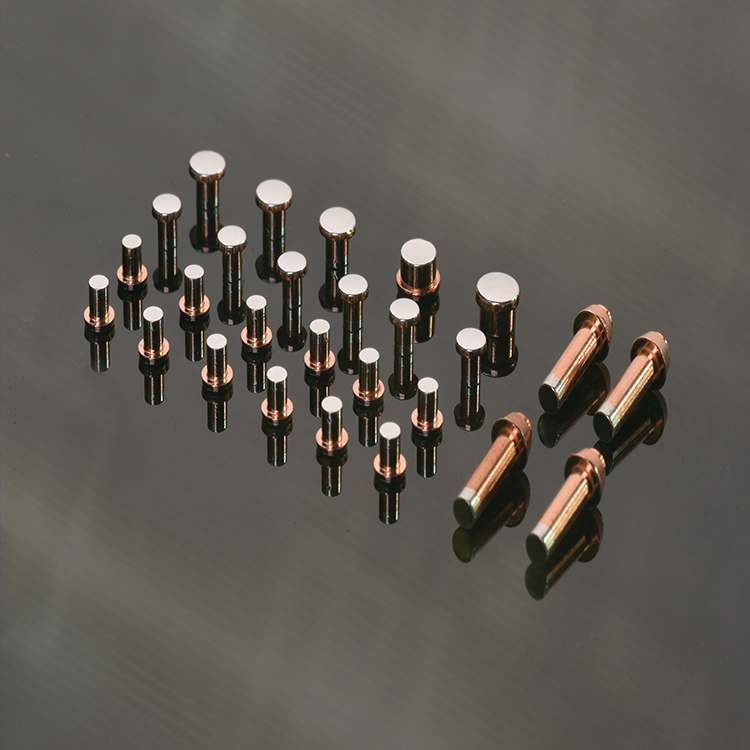

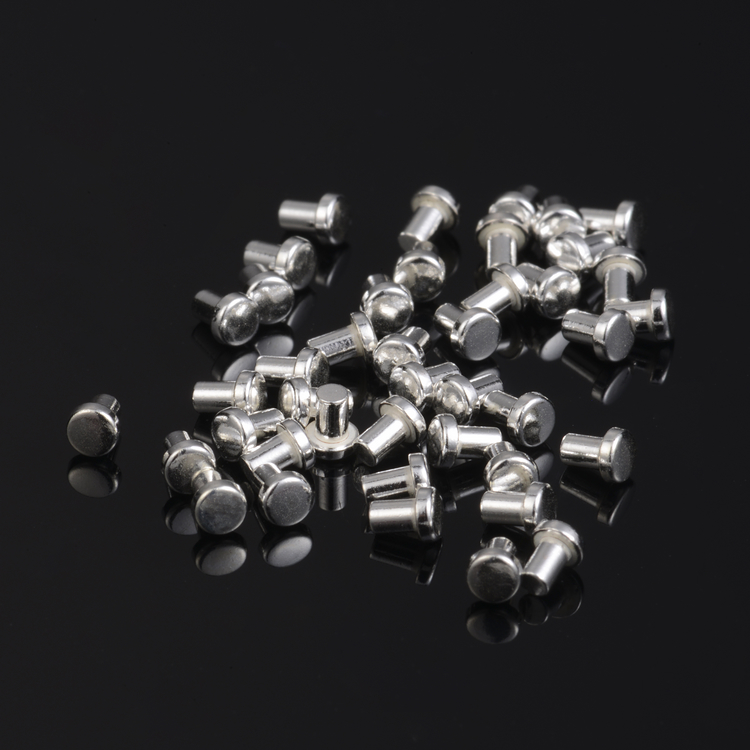

Welding Assembly

We import B-5000 welding machine from Bihler in Germany, we can weld 200-300pcs per minutes.

Two basic processes are used in contact welding: individual contact pieces are welded onto solid or pre-stamped carrier strips or the stamped contact parts are manufactured from semi-finished strip with already pre-attached contact material. During welding of contact pieces the contact material is attached from either profiles (tapes), wire segments or in tip form. The maximum contact area size for high rate welding while maintaining close manufacturing tolerances is 5 x 5 mm².

Depending on the application contact materials used are based on gold, palladium or silver. To utilize the most reliable and economical manufacturing process the contact materials usually have an easily weldable backing.

|

Production process |

Strip uncoiling-strip leveling-Pre punching-Coin and weld-Final punching |

|

Rate of production |

300-450pcs/min |

|

Strip width |

≤60mm |

|

Strip thickness |

0.1-1.0mm |

|

Ag、AgNi、AgCu、AgFe,etc. |

|

|

Contact wire diameter range |

Φ0.4 – Φ2.5 mm |

|

Contact diameter |

Φ1-Φ4.5mm |

|

Contact height |

0.2-2.0mm |

|

Bonding strength |

l 80-800N l Longitudinal welding line≥Contact wire diameter) l Transverse welding line≥1/2Contact wire diameter) |

Stamped parts with semi-finished contact strips

Stamped parts from semi-finished contact strip are economically produced from continuous strip. Contact material produced in our mill facilities are based on gold, palladium and silver. Copper and copper alloys are used as base carrier materials.

Clad Stampings

Many contact applications require thicker precious metal layers. These cannot be applied to the substrates economically by electroplating processes. In addition contact materials with very specific physical and mechanical properties are often required. These materials from gold-palladium alloys or based on silver are made by either alloy melting or powder metallurgy. The combination of contact and base material is achieved by cladding processes such as cold roll-cladding or hot roll-bonding.

Stamped Parts from Toplay Profiles

DODUCO manufactures contact bimetals in strip form by brazing of flator shaped strips to carrier materials followed by profile rolling. These are the basis for customer specified contact parts with raised precious metal segments for highly demanding applications.

Stamped Parts from seam-welded strips

The main advantage of seam-welded strip material for the production of contact stampings is the limited area of the weld zone. This results in softening of spring hard base materials only in the immediate weld effected area. The contact layers consist mainly of solid contact materials or composite contact profiles or weld.

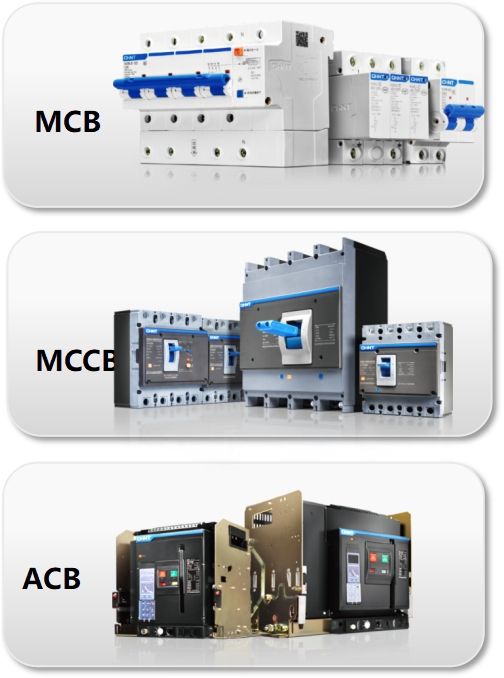

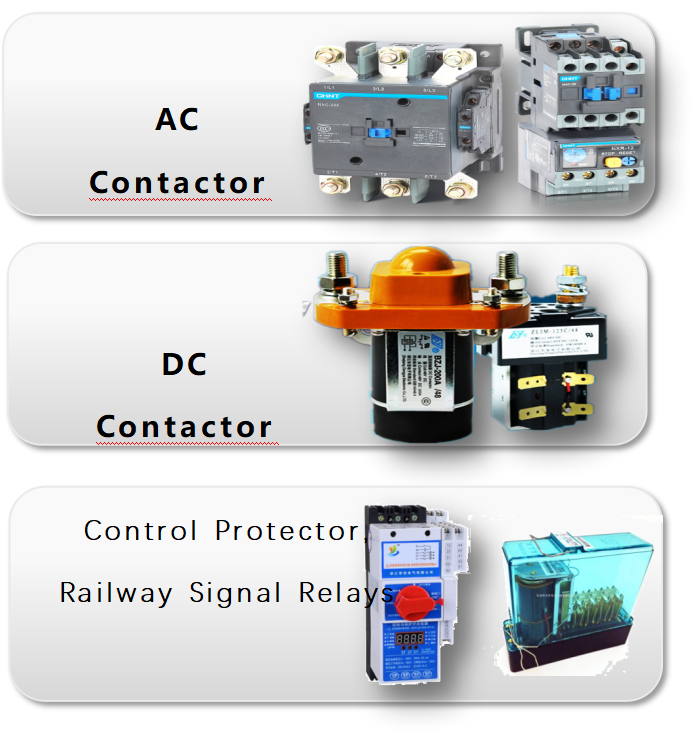

Application

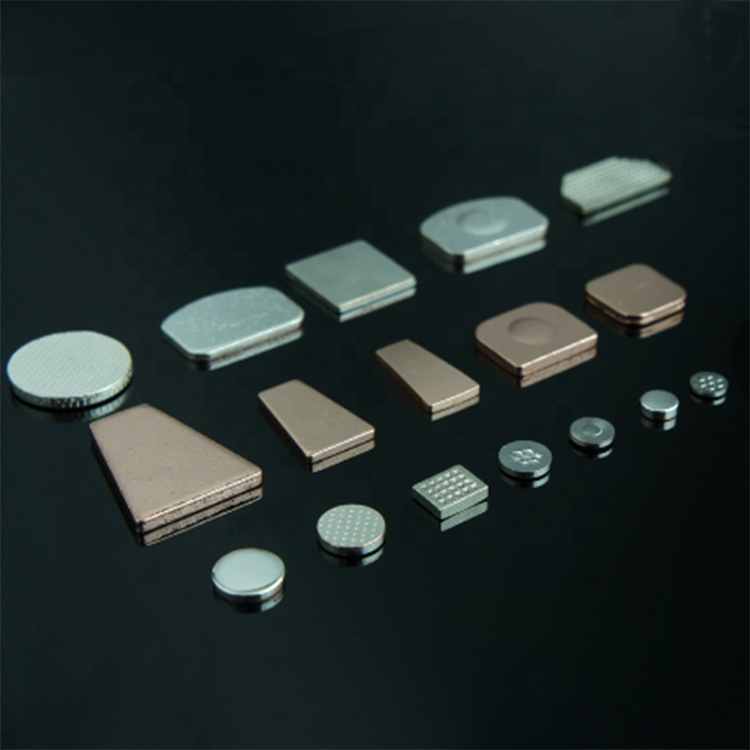

Product detail pictures:

Related Product Guide:

We have been proud from the higher consumer gratification and wide acceptance due to our persistent pursuit of high quality both on product or service and service for China Hot New Products Electrical Contact Points - Welding Assembly - ZHJ Manufacturer and Supplier | ZHJ , The product will supply to all over the world, such as: Istanbul , Swiss , Uganda , Upon today, we have customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to provide the highest quality products with best price. We are looking forward to doing business with you.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.