Current silver price increase a lot. Some company is trying to find a replace material to reduce the cost. So this topic is to discuss in what application filed can tungsten replace silver alloy materials.

Due to its unique properties, tungsten can serve as a substitute for silver alloys in specific application areas, but it’s important to note that they are not direct replacements in all aspects. Feasibility depends entirely on the core requirements of the application scenario.

In simple terms:

* If extremely high electrical/thermal conductivity is needed, tungsten cannot replace silver alloys.

* If extremely high hardness, wear resistance, high-temperature resistance, and stability are needed, tungsten is a far superior choice compared to silver alloys.

Below is a detailed analysis of the specific application areas where tungsten can replace silver alloy materials:

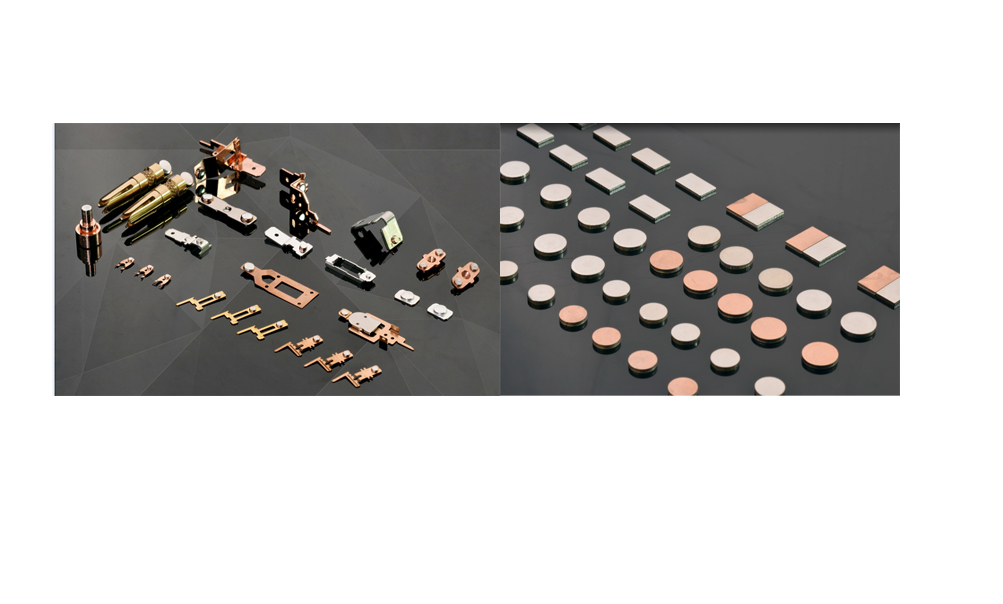

Electrical Contact Materials

This is the most classic and critical area where tungsten substitutes for silver alloys. Electrical contact materials require a combination of good conductivity and resistance to arc erosion.

* Target for Replacement: Silver-based electrical contact materials, such as silver-cadmium oxide, silver-nickel, silver-graphite, etc.

* Application Scenarios: Circuit breakers, switches, relays, automotive starters, etc.

* Reason for Substitution:

– Disadvantages of Silver Alloys: Silver has excellent conductivity but is soft and has a low melting point (approx. 960°C). Under the arc generated when breaking a circuit, silver contacts are prone to melting, splattering, and erosion, leading to a shorter lifespan.

– Advantages of Tungsten:

High Melting Point (3410°C): Can withstand extreme arc temperatures without melting.

High Hardness: Excellent wear resistance, leading to a long mechanical life.

Arc Erosion Resistance: Tungsten forms a heat-resistant oxide layer on its surface under arc action, resulting in slower wear.

* Form of Substitution:

Pure Tungsten Contacts: Used in heavy-duty applications where conductivity requirements are moderate, but demands for arc resistance and wear resistance are extremely high.

Silver-Tungsten Composite Materials: This is the most common solution. Tungsten and silver are composited using powder metallurgy techniques (e.g., AgW30, AgW50, AgW70). This material combines the excellent conductivity of silver with the arc resistance and high hardness of tungsten, offering performance superior to plain silver alloys. Here, tungsten acts as a reinforcing phase for silver, partially replacing other metal oxides found in silver alloys.

High-Temperature and Wear-Resistant Components

* Target for Replacement: Silver-based brazing filler metals or silver alloy wear-resistant components used in certain high-temperature, abrasive environments.

* Application Scenarios: Components for high-temperature furnaces, die-casting molds, wear-resistant liners, armor-piercing penetrators, etc.

* Reason for Substitution:

Disadvantages of Silver Alloys: Silver’s strength drops drastically at high temperatures; it softens and deforms easily, and its wear resistance is mediocre.

Advantages of Tungsten: Extremely High Strength at Elevated Temperatures: Maintains high strength even above 1000°C.

Excellent Wear Resistance: Hardness is far superior to any silver alloy.

Low Thermal Expansion Coefficient: Good dimensional stability, less prone to deformation with temperature changes.

Welding and High-Temperature Brazing

* Target for Replacement: In specific applications, tungsten can be used as electrode or fixture material, replacing components that might be made from silver.

* Application Scenarios:

Tungsten Electrodes: Essential in TIG welding. Their high melting point and electron emission capability make them irreplaceable by silver alloys.

High-Temperature Brazing Fixtures: When brazing aerospace components, process temperatures can be very high (exceeding 1000°C). Fixtures made of silver alloy would melt or deform, whereas those made from tungsten or molybdenum remain stable.

Summary: Performance Comparison of Tungsten vs. Silver Alloys

| Performance Indicator | Tungsten | Silver Alloys | Conclusion |

| Electrical Conductivity | Poor (≈1/3 of Silver) | Excellent | Silver alloys are superior, this is their core advantage. |

| Thermal Conductivity | Good (≈1/2 of Silver) | Excellent | Silver alloys are better. |

| Melting Point | Extremely High (3410°C) | Low (≈960°C) | Tungsten is superior, forming the basis for substitution. |

| Hardness | Extremely High | Low | Tungsten is superior, excellent wear resistance. |

| Density | High (19.25 g/cm³) | Medium-High (~10.5 g/cm³) | Tungsten is heavier, a disadvantage in weight-sensitive applications. |

| Cost | Relatively High | High (strongly influenced by silver price) | Depends on the specific material and quantity. |

| Processability | Poor (Hard and brittle, difficult to machine) | Good (Ductile, easy to form) | Silver alloys are easier to manufacture and form.

|

Conclusion and Recommendations

When considering replacing a silver alloy with tungsten, follow this thought process:

1.Is the Primary Factor High-Temperature Resistance, Wear Resistance, or Arc Resistance?

Yes: Tungsten or silver-tungsten composites are excellent substitute choices, significantly improving component lifespan and reliability. This is especially true in electrical contacts and high-temperature structural parts.

No: If the application’s core requirement is conductivity, thermal conductivity, or requires good plastic deformation processing, then tungsten is not a suitable replacement. You should stick with silver alloys or other highly conductive metals (like copper alloys).

2. Consider Composite Materials:

In many cases, silver-tungsten composite materials offer the best compromise, providing the “best of both worlds.” They retain the good conductivity of silver while introducing the high-temperature resistance and wear resistance of tungsten. This is the optimal solution for replacing traditional silver alloy electrical contact materials.

In summary, tungsten is not a universal substitute for silver alloys. Instead, it is an excellent replacement in specific areas where performance requirements fundamentally shift (from pursuing conductivity to pursuing durability).

Post time: Oct-20-2025