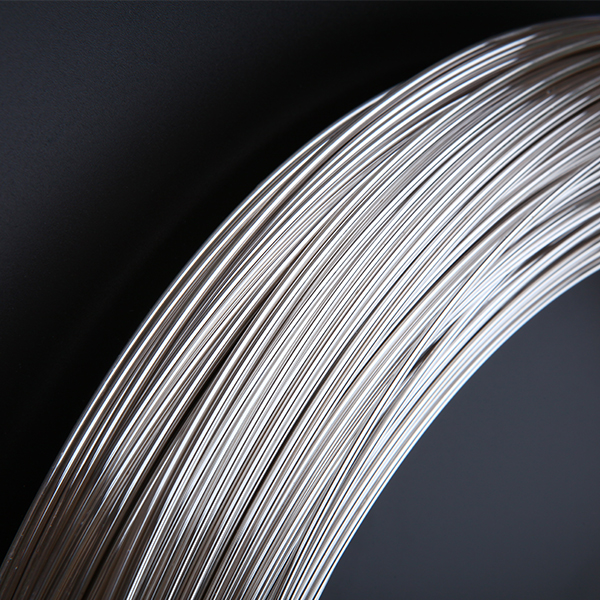

IiNcingo zeSilver Alloy

| Isicelo: |

| Abafowunelwa, ii-circuit breakers, thermostats, iiswitshi ezikrelekrele, njl |

| Isixhobo: |

| Ag/FAg,AgNi,AgCdO,AgZnO,AgSnO2,AgSnO2In2O3 |

Ag- FAg

1. IMicrostructure

2. Inkcazo ngokubanzi

Isilivere kunye nesilivere esulungekileyo (i-FAg) inombane ophezulu kakhulu kunye ne-thermal conductivity, ukuchasana okuphantsi kunye nokuzinza koqhagamshelwano, kunye nokusebenza kakuhle.Ukumelana nesilivere kukhukuliseko lwe-arc kunye ne-welding yokudibanisa iyancipha, amandla omatshini aphantsi, Ngenxa yobuninzi be-nickel kwi-fine grain silver, ukuchasana nokhukuliseko lwe-arc kunye namandla omatshini aphezulu kunesilivere.

3. Umda wosetyenziso

Isetyenziswa kakhulu kwizixhobo zangoku ezisezantsi, ezinje ngeereyilayi, izibali-xesha, iiswitshi ezincedisayo kwizixhobo zendlu, iiswitshi zolawulo, njl.njl.

4. IiPropati zeMathiriyeli

| Ag | I-FAg | |||

| Iingcebiso | Iingcingo | Iingcebiso | Iingcingo | |

| Umxholo we-Ag (wt.%) | ≥99.95 | ≥99.95 | 99.85 | 99.85 |

| Ubuninzi (g/cm3) | ≥10.48 | ≥10.48 | ≥10.40 | ≥10.40 |

| Elec.Ukuxhathisa (pQ•cnn) | ≤2.10 | ≥1.80 | ≥2.10 | ≥1.85 |

| Ubulukhuni HV | ≥40 | ≥60 | ≥45 | ≥65 |

| Amandla Okuqina (MPa) |

| 230-380 |

| 250-380 |

| Ubude (%) |

| 2-30 |

| 2-30 |

| Inkqubo yokuvelisa | Extruding-Rolling | Ukukhupha -Umzobo | Extruding-Rolling | Ukukhupha -Umzobo |

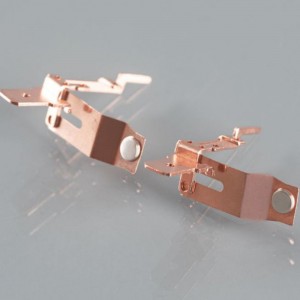

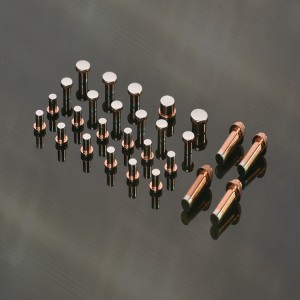

5. Iintlobo zeeMveliso

AgNi

1. IMicrostructure

2. Inkcazo ngokubanzi

Izixhobo ze-AgNi zinokuxhathisa okuphezulu kukhukuliseko lwe-arc kunye ne-welding yoqhagamshelwano kune-Ag okanye i-FAg.Zombini iipropathi ziphuculwe ngokunyusa umxholo we-Ni.Zonke iimathiriyeli ze-AgNi zibonisa ukusebenza kakuhle kwaye kulula ukuzidibanisa ukunxibelelana nabaxhasayo.Utyekelo oluphantsi ekugqithiseni izinto kwizicelo zeDC.Iimathiriyeli ze-AgNi zizinto ezikhusela indalo esingqongileyo.

3. Umda wosetyenziso

Izixhobo zoqhagamshelwano ze-AgNi zifumana uluhlu olubanzi lwesicelo kwizixhobo zokutshintsha umbane ophantsi.Zisetyenziswa kwii-relays, ii-contactants ezincinci, izibane zokukhanya, izilawuli zeqondo lokushisa kunye neenguqu ezikhuselayo (zisetyenziswa kwiibini zoqhagamshelwano ze-asymmetric, umzekelo, ngokuchasene ne-AgC, i-AgZnO okanye i-AgSnO2 izinto).

4. IiPropati zeMathiriyeli

| Iingcingo | AgNi | AgNi | AgNi | Ag Ni | AgN i | AgNi |

| Ni Umxholo (wt.%) | 10±1 | 12±1 | 15±1 | 15±1 | 20±1 | 30±1 |

| Ubuninzi (g/cm3) | ≥10.25 | ≥10.20 | ≥10.15 | ≥10.15 | ≥10.05 | ≥9.80 |

| Elec.Resistivity (pC2•cm) | ≤1.95 | ≤2.05 | ≤2.05 | ≤2.10 | ≤2.15 | ≤2.50 |

| Ubulukhuni HV | ≥75 | ≥70 | ≥80 | ≥80 | ≥80 | ≥80 |

| Amandla Okuqina (MPa) | 240-450 | 240-450 | 250-360 | 280-460 | 260-380 | 260-380 |

| Ubude (%) | 5-30 | 5-30 | 5-30 | 5-28 | 2-28 | 2-25 |

| Inkqubo yokuvelisa | Sintering-Extruding | |||||

5. Iintlobo zeeMveliso

AgCdO

1. IMicrostructure

2. Inkcazo ngokubanzi

Abafowunelwa be-AgCdO ngamalungu eqela labona basetyenziswa kakhulu kwindawo yezixhobo zombane zombane ophantsi.Badibanisa ukuxhathisa okwanelisayo ngokuchasene ne-welding yoqhagamshelwano kunye nokumelana nokukhukuliseka kwe-arc kunye nokuchasana okuphantsi ngokufanelekileyo kubomi bayo obupheleleyo benkonzo.Ziveliswa ngeendlela ezimbini ezahlukeneyo, i-pre-oxidation-sintering-extruding kunye ne-oxidation yangaphakathi.Kuzo zombini ezi meko umxholo we-Cd0 unokususela kwi-10 ukuya kwi-20wt.. Nangona kunjalo, i-Cd kunye ne-Cd0 zithathwa njengengozi kwimpilo kunye nokusingqongileyo.Ngesi sizathu ukusetyenziswa kwezinto ze-AgCdO kuya kuvalwa kumazwe amaninzi.

3. Umda wosetyenziso

Isetyenziswa kakhulu phantse kulo lonke uhlobo lwezixhobo zokutshintsha ombane ophantsi.Ngokuqhelekileyo zisetyenziswa kwii-microswitches, ii-relays, izitshixo zokukhanya, ii-contactors, iiswitshi zezixhobo zendlu, ezinye iindidi zokukhusela ezikhuselayo, kunye nakwiintlobo ezithile ze-breaker circuit.

4. IiPropati zeMathiriyeli

| Iingcingo | AgCdO | AgCdO | AgCdO | AgCdO | AgCdO | AqCd0 | AgCdO |

| Umxholo weCdO(wt.%) | 10±1 | 13.5±1 | 15±1 | 10±1 | 12±1 | 15±1 | 17±1 |

| Ubuninzi (g/cm3) | ≥10.05 | ≥9.95 | ≥9.90 | ≥10.10 | ≥10.05 | ≥9.95 | ≥9.80 |

| Elec.Resistivity (1.10•cm) | ≤2.25 | ≤2.35 | ≤2.40 | ≤2.10 | ≤2.15 | ≤2.25 | ≤2.40 |

| Ubulukhuni HV | ≥70 | ≥75 | ≥75 | ≥70 | ≥70 | ≥75 | ≥75 |

| Amandla Okuqina (MPa) | 260-350 | 260-380 | 260-380 | 260-350 | 260-380 | 260-380 | 260-400 |

| Ubude (%) | 6-20 | 6-20 | 6-20 | 8-25 | 8-25 | 8-25 | 5-25 |

| Inkqubo yokuvelisa | Pre-oxidation-Sintering-Extruding | I-Oxidation yangaphakathi | |||||

5. Iintlobo zeeMveliso

AgZnO

1. IMicrostructure

2. Inkcazo ngokubanzi

Ukuchasana okuphezulu ngokuchasene ne-welding yoqhagamshelwano ibonakalisa izinto ze-AgZnO.Zikwabonisa ukuxhathisa okulungileyo ngokuchasene nokhukuliseko lwe-arc.Uxhathiso loqhagamshelwano lwe-AgZnO luthande ukuba phezulu kunolo lwe-AgCd0.I-AgZnO inokuveliswa ngendlela ye-pre-oxidation-sintering—i-extruding, i-mixing-compacting-sintering techniques ngokunjalo nange-oxidation yangaphakathi.Izinto ze-AgZnO zizinto ezikhusela indalo.

3. Umda wosetyenziso

Isetyenziswa kakhulu kwi-circuit breakers, ngakumbi kwi-universal circuit breakers.Eminye imimandla yokusetyenziswa kukutshintsha kokhuseleko lweemoto, ii-breaker circuit zangoku ezishiyekileyo kunye nee-AC relays.

4. IiPropati zeMathiriyeli

| Iingcingo | AgZnO | AgZnO |

| Umxholo we-ZnO(wt.%) | 8±1 | 10±1 |

| Ubuninzi (g/cm3) | .9.65 | 9.60 |

| Elec.Resistivity (NO•cm) | 2.25 | 2.35 |

| Ubulukhuni HV | E30 | 85 |

| Amandla Okuqina (MPa) | 285-350 | 285-350 |

| Ubude (%) | 15-25 | 12-20 |

| Inkqubo yokuvelisa | Pre-oxidation -Sintering-Extruding | |

5. Iintlobo zeeMveliso

AgSnO2

1. IMicrostructure

2. Inkcazo ngokubanzi

I-AgSnO2/AgSn021n203 zizixhobo zoqhagamshelwano zombane eco-friendly.Banemisebenzi emihle kwi-anti-rosion kunye ne-anti-welding properties, kwaye banepropathi efanelekileyo yokudlulisa impahla kwi-DC switching circuit.Iinkqubo eziphambili zokwenziwa kwenkqubo ye-oxidation yangaphakathi, inkqubo ye-oxidation yangaphambili, inkqubo ye-powder metallurgy, inkqubo yokwaleka kweekhemikhali, njl..

3. Umda wosetyenziso

Isetyenziswa kakhulu kwiindidi ezahlukeneyo zabanxibelelanisi, iireyilayi, izaphuli zesekethe kunye nokutshintsha, njl.

4. IiPropati zeMathiriyeli

AgSnO2

| Iingcingo | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSn02 |

| SnO2 Umxholo (wt.%) | 10±1 | 10±1 | 12±1 | 12±1 | 15±1 |

| Ubuninzi (g/cm3) | ≥9.90 | ≥9.95 | ≥9.85 | ≥9.85 | ≥9.5 |

| Elec.Ukuxhathisa (pO•cm) | ≤2.15 | ≤2.30 | ≤2.30 | ≤2.30 | ≤2.81 |

| Ubulukhuni HV | ≥85 | ≥95 | ≥70 | ≥75 | ≥85 |

| Amandla Okuqina (MPa) | 295-350 | 290-385 | 230-350 | 230-285 | 250-330 |

| Ubude (%) | 15-25 | 15-25 | 15-25 | 18-30 | 15-25 |

| Inkqubo yokuvelisa | Pre-oxidation-Sintering-Extruding | Ukwaleka kweMichiza | Ukuxuba-Sintering-Extruding | ||

AgSnO2In203

| Iingcingo | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 |

| Umxholo we-Ag (wt.%) | 90±1 | 88±1 | 92±1 | 88±1 | 85.5±1 |

| Ubuninzi (g/cm3) | ≥9.95 | ≥9.95 | ≥9.96 | ≥9.91 | ≥9.72 |

| Elec.Ukuxhathisa (10•cm) | ≤2.38 | ≤2.45 | ≤2.25 | ≤2.35 | ≤2.55 |

| Ubulukhuni HV | ≥100 | ≥100 | ≥90 | ≥95 | ≥95 |

| Amandla Okuqina (MPa) | 320-450 | 320-450 | 320-450 | 320-450 | 320-450 |

| Ubude (%) | 15-25 | 15-25 | 18-30 | 18-30 | 18-30 |

| Inkqubo yokuvelisa | Pre-oxidation-Sintering-Extruding | I-Oxidation yangaphakathi | |||

5. Iintlobo zeeMveliso

AgSnO2In2O3

1. Inkcazo ngokubanzi

2. IMicrostructure

I-AgSnO2lAgSn021n203 zizixhobo zoqhagamshelwano zombane eco-friendly.Banemisebenzi emihle kwi-anti-rosion kunye ne-anti-welding properties, kwaye banepropathi efanelekileyo yokudlulisa impahla kwi-DC switching circuit.Iinkqubo eziphambili zokuvelisa yinkqubo ye-oxidation yangaphakathi, inkqubo ye-pre-oxidation, inkqubo ye-powder metallurgy, inkqubo yokugubungela imichiza, njl.

3. Umda wosetyenziso

Isetyenziswa kakhulu kwiindidi ezahlukeneyo zabanxibelelanisi, iireyilayi, izaphuli zesekethe kunye nokutshintsha, njl.

4. IiPropati zeMathiriyeli

AgSnO2

| Iingcingo | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSn02 |

| SnO2 Umxholo (wt.%) | 10 ±1 | 10 ±1 | 12±1 | 12±1 | 15 ±1 |

| Ubuninzi (g/cm3) | ≥9.90 | ≥9.95 | ≥9.85 | ≥9.85 | ≥9.5 |

| Elec.Ukuxhathisa (p0•cm) | ≤2.15 | ≤2.30 | ≤2.30 | ≤2.30 | ≤2.81 |

| Ubulukhuni HV | ≥85 | ≥95 | ≥70 | ≥75 | ≥85 |

| Amandla Okuqina (MPa) | 295-350 | 290-385 | 230-350 | 230-285 | 250-330 |

| Ubude (%) | 15-25 | 15-25 | 15-25 | 18-30 | 15-25 |

| Inkqubo yokuvelisa | Pre-oxidation-Sintering-Extruding | Ukwaleka kweMichiza | Ukuxuba-Sintering-Extruding | ||

AgSnO2In203

| Iingcingo | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 | AgSnO2 |

| Umxholo we-Ag (wt.%) | 90±1 | 88±1 | 92±1 | 88±1 | 85.5±1 |

| Ubuninzi (g/cm3) | ≥9.95 | ≥9.95 | ≥9.96 | ≥9.91 | ≥9.72 |

| Elec.Ukuxhathisa (p0•cm) | ≤2.38 | ≤2.45 | ≤2.25 | ≤2.35 | ≤2.55 |

| Ubulukhuni HV | ≥100 | ≥100 | ≥90 | ≥95 | ≥95 |

| Amandla Okuqina (MPa) | 320-450 | 320-450 | 320-450 | 320-450 | 320-450 |

| Ubude (%) | 15-25 | 15-25 | 18-30 | 18-30 | 18-30 |

| Inkqubo yokuvelisa | Pre-oxidation-Sintering-Extruding | I-Oxidation yangaphakathi | |||